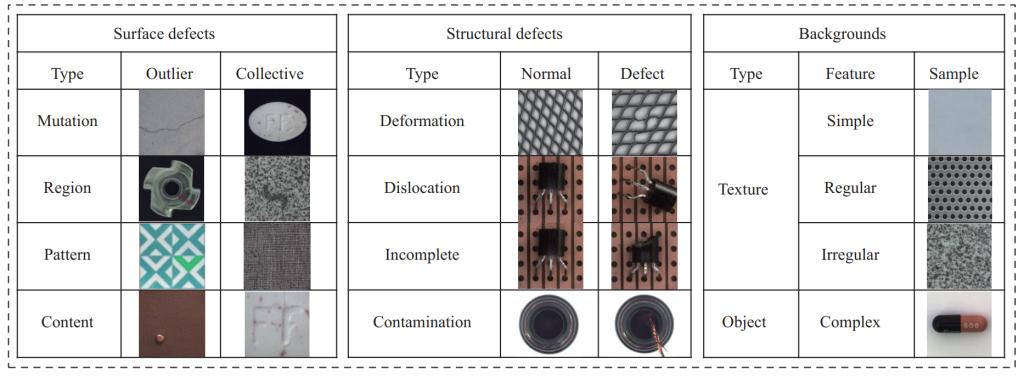

基于深度学习的工业缺陷检测方法可以降低传统人工质检的成本,提升检测的准确性与效率,成为计算机视觉领域的新兴热点之一。本综述对工业缺陷检测的任务定义、难点、挑战、主流方法、公共数据集及评价指标等进行了全面归纳。按照实际数据标注情况,划分出缺陷模式已知、缺陷模式未知与少量缺陷标3研究任务设置,并根据方法类型作进一步归纳与分析。探讨了各方法的性能优劣与适用场景。阐明了方法与实际应用需求的关联性。此外,本文还归纳了方法部署中的关键辅助技术,总结了现有方法在实际产业落地中存在的局限性。最后,本文对该领域未来的发展趋势和潜在研究方向进行了展望。

Deep-learning-based industrial defect detection methods provide compelling benefits in reducing the cost spent on manual product inspection, while improving inspection accuracy and efficiency. Thus, industrial defect detection has become one of the hotspots in computer vision in recent years. This survey aims to make a comprehensive introduction of industrial defect detection, which mainly spans its definition, difficulties, challenges, mainstream methods, open datasets, and evaluation protocols. Based on the difference of the provided annotations of different datasets in practical scenarios, we categorize most methods into three task settings: known defects, unknown defects, and few-shot defects. We go over these methods in further depth and illustrate a detailed analysis. We expound the connections between different algorithms and actual demands to present a clear picture of how different algorithms evolve. In addition, this paper summarizes some useful strategies that can effectively improve defect detection performance. Finally, based on our understanding of this area, we conclude several limitations of existing methods in practical applications as well as several directions of future research that embrace further efforts.

文章链接:http://scis.scichina.com/cn/2022/SSI-2021-0336.pdf

发表刊物:中国科学: 信息科学, 2022, 52: 1002–1039, doi: 10.1360/ SSI-2021-0336